3 Phase Motor Terminals

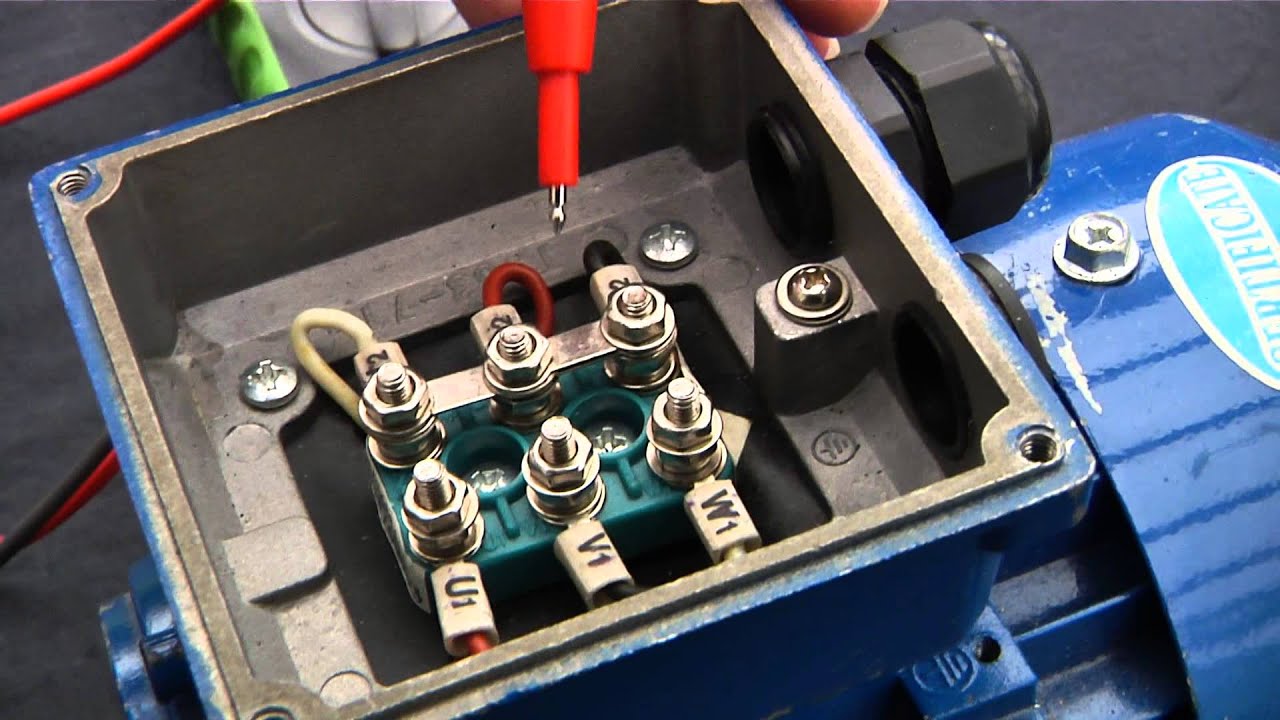

Check the connection bar for terminal u v and w.

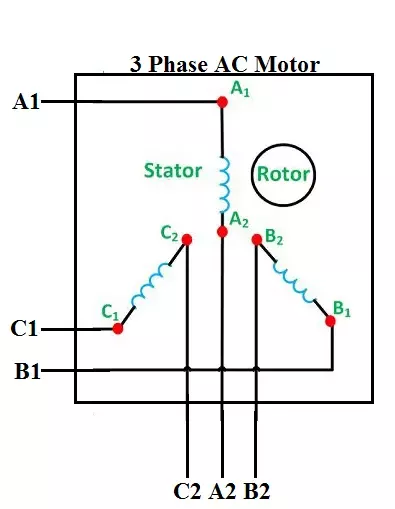

3 phase motor terminals. The 3 phase motor is a rugged piece of equipment but as with everything man made there comes a time when this beautiful piece of machinery fails either due to. This is done by wiring the terminal board as shown in the wiring diagram to the right. For example 2 pole motor three phase has 6 nest 3 coilsnest and 6 leads. The marking of the terminal board is also defined in iec 60034 8.

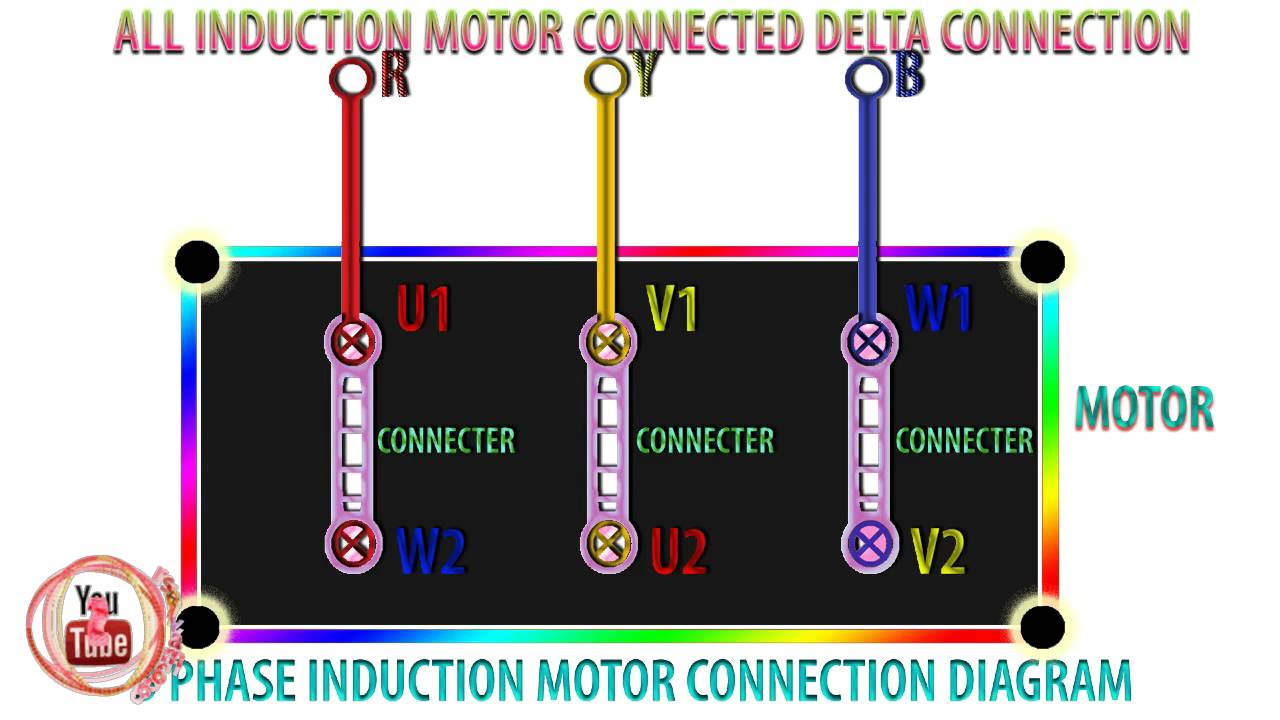

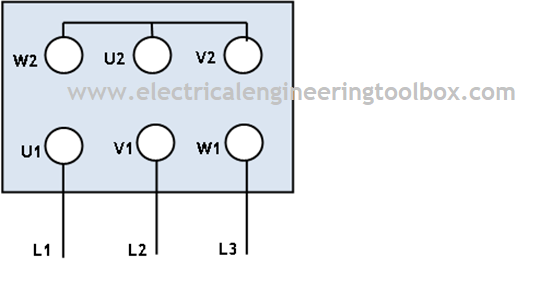

The windings are connected in star y connection or in delta d connection according to iec 60034 8. In normative for manufacture electrical motors exist two polit one din convection europe and nema american countries in normative din use for terminals leads the letter u v w that means coil head and letter xy z means ending coil. A three phase motor must be wired based on the diagram on the faceplate. For three phase motors connection type is either star y or delta ac motor winding continuity test using a multimeter check the continuity of motor winding from phase to phase u to v v to w w to u each phase to phase must have a continuity if winding is ok.

Delta connection terminal motor. The w2u2v2 terminal set is the star side of the 3 phase motor while the u1viw1 is the delta side of the motor connected to the supply voltage. This video explains how to connect 3 phase induction motor terminal and motor winding circuits terminal connection how can wiring in the phase line and 3 phase motor connection explains star and. If our power supply is 200 vac 3 phasewe need to connected the cooper bar terminal in delta positionit mean a connection are u1 with w2v1 with u2 and w1 with u2it just need to follow the diagram shown in motor nameplate.

To use three phase electricity a motor needs windings spaced 120 degrees apart. Three phase motors wiring diagrams and markings of terminals. That being said there is a wide range of different motors and what you have on hand can be completely different. Three phase electric motors use three different electric legs with a 13 cycle lag between them.

Three phase motors are more efficient than single phase motors and are commonly found in applications requiring more than 75 horsepower. If any particular phase. Although the national electric code does not specify specific conductor colors for three phase current it is common to use black red and blue wires to identify lines l1 l2 and l3 respectively. In the united states for low voltage motors below 600v you can expect either 230v or 460v.

A three phase motors large size and high starting torque usually limit its use to industrial settings. The motors starter wires directly to the motors wire terminals.