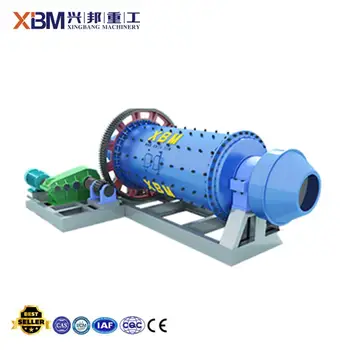

Ball Mill

Ball mills are a fundamental part of the manufacturing industry in the usa as well as around the world.

Ball mill. In addition to well proven mixing and size reduction processes these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloying. In stock and ready to ship. The precision machineries we produce have good stability. Ball mill is one of the most imporatant machines in ore derssing plant.

Ball end mills are very durable and come with an array of surface coatings tailored for milling a wide range of materials from plastics to titanium and steel alloys. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cutting. The final product of the gold ball mill is ieal and also always can be use on cosmetic. Pebble mills are a type of ball mill and are also used to reduce the size of hard materials down to 1 micron or less.

Federal equipment company also offers used ball and pebble jar mills with various capacities and linings so you can find one that works for your manufacturing needs. Ball mills crush material into various sizes and extract resources from mined materials. The organocatalytic activity of the methyl ester of s proline s phenylalanine ss 2 in the asymmetric aldol reaction between cyclohexanone and acetone with various aromatic aldehydes under solvent free conditions in a ball mill has been evaluated. It can be used to process many materials including gold copper granite quartz pebble limestones etc.

Ball mill is a key equipment to re crush primary crushed materials. Ball mill pebble jar mills. The chocolate ball milling machine are produced by the qualified and certificated china ball mill machine manufacturer. By purchasing your used ball mill or pebble mill from federal equipment company you will be purchasing from a trusted name in processing equipment.

This chocolate ball mill grinding machine is with fine refining of chocolate compounds creams daily application chemical materials and other low fat masses. It works on the principle of impact. Tungsten carbide mill ball. Aa dipeptide ss 2 catalyzed the stereoselective formation of the expected aldol products with higher diastereo and enantioselectivity relative to similar reactions in solution up to 919 antisyn diastereomeric ratio and up to 95.

Ball mills are widely used in cement silicate products 52555 new building materials refractory materials fertilizer ferrous and non ferrous metals and glass ceramics and other production industries. Iron core pu mill ball. The turn disc rotates in one direction while the bowls rotate in the opposite direction. Choose from our selection of carbide ball end mills high speed steel ball end mills cobalt steel ball end mills and more.

Today we will learn about difference between sag mill vs ball mill. The ball mill system consists of one turn disc turn table and two or four bowls. The centrifugal forces created by the rotation of the bowl around its own axis together with the rotation of the turn disc are applied to the powder mixture and milling balls in the bowl. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

Planetary ball mills are used wherever the highest degree of fineness is required. The high energy input is a result of an unrivaled speed of 2000 min 1 and the optimized jar design. Ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes. The emax is an entirely new type of ball mill for high energy milling.