Diagram Of Material

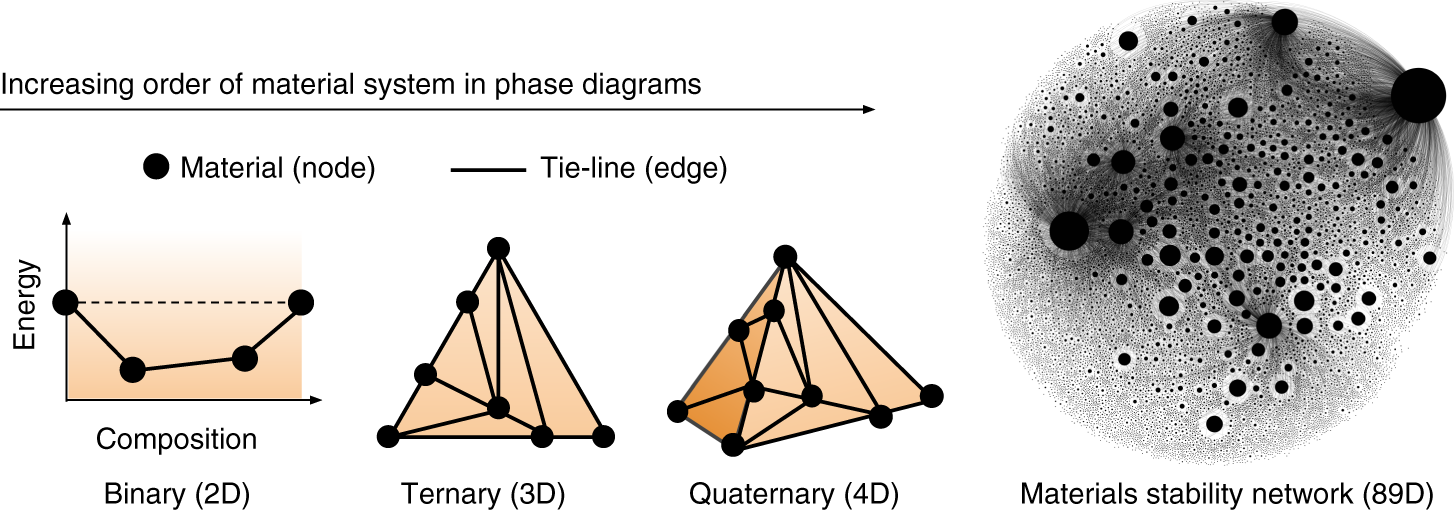

Relationship between the phase diagram and properties of material.

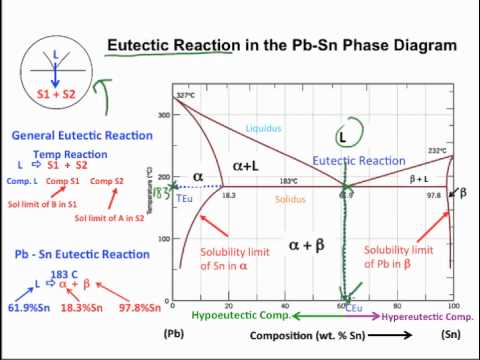

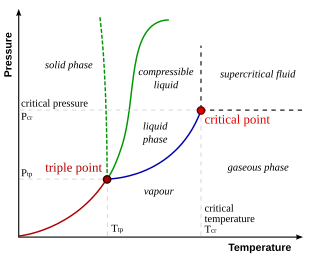

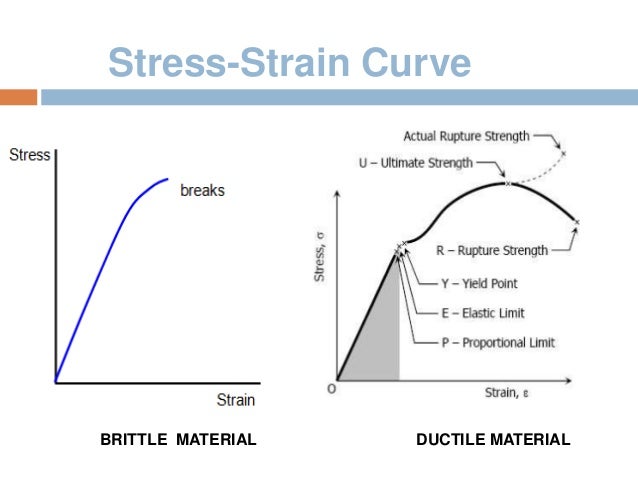

Diagram of material. Systematic selection of the best material for a given application begins with properties and costs of candidate materials. It increase both side of eutectic point. A phase diagram in physical chemistry engineering mineralogy and materials science is a type of chart used to show conditions pressure temperature volume etc at which thermodynamically distinct phases such as solid liquid or gaseous states occur and coexist at equilibrium. Metallic engineering materials are classified as either ductile or brittle materials.

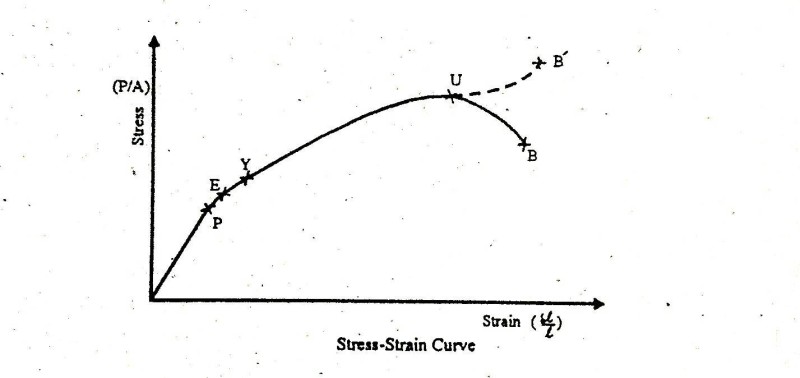

Strength of materials also called mechanics of materials is a subject which deals with the behavior of solid objects subject to stresses and strains. Larger the area of mushy zone. There are two different versions of a material flow bubble diagram. Fluidity is maximum for pure material at eutectied.

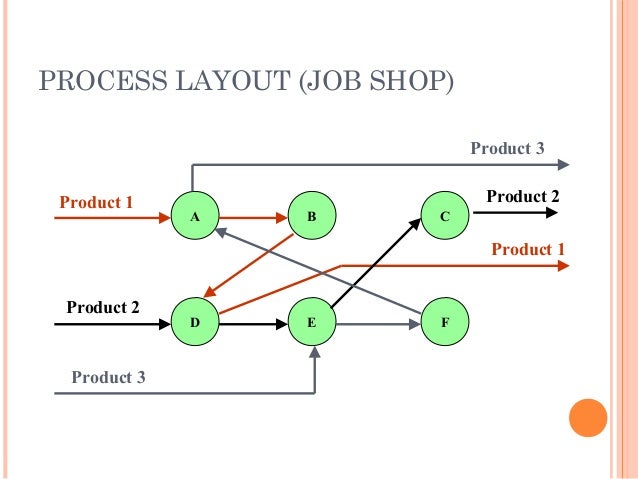

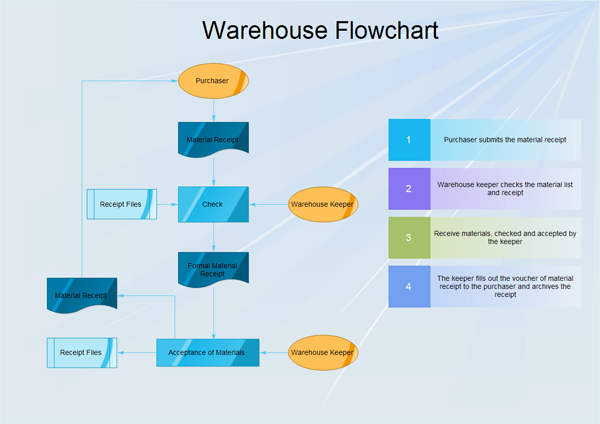

How to make a material flow bubble diagram. Lower will be the fluidity. An automated workflow tool. Msd is normally developed from simplified process flow diagrams pfds by process engineer material engineer and the metallurgist of project.

Solubility limitof a component in a phase is the maximum amount of the component that can be dissolved. Therefore the understanding of phase diagrams for alloy systems is very important. As such they are faster to make and can show a larger number of material flows simultaneously. Material selection diagram msd is an engineering drawing which shows material selection information and specification of the piping and equipment in a process facility.

Introduction to materials science chapter 9 phase diagrams 3 solvent host or major component in solutionsolute minor component. Here is a general workflow diagram showing the main processes of material management. The stress strain diagram differs in form for various materials. Material selection is a step in the process of designing any physical object.

In other words material management is also defined as a scientific technique concerned with planning organizing control of flow of materials from their initial purchase to destination. In the context of product design the main goal of material selection is to minimize cost while meeting product performance goals. Bubble diagrams show you the material flow in detail but do not go into details of the information flow. In materials science the strength of a material is its ability to withstand an applied load without failure.

A ductile material is one having relatively large tensile strains up to the point of rupture like structural steel and. The diagram shown below is that for a medium carbon structural steel.