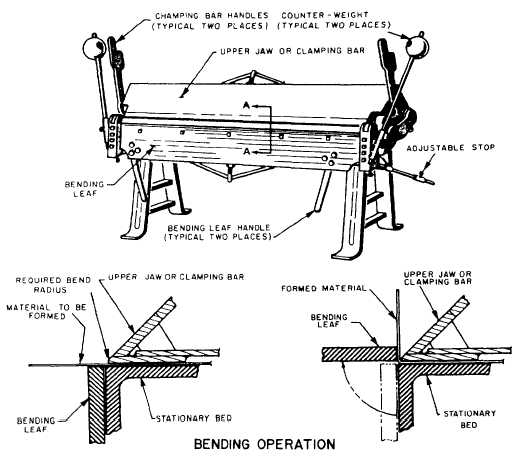

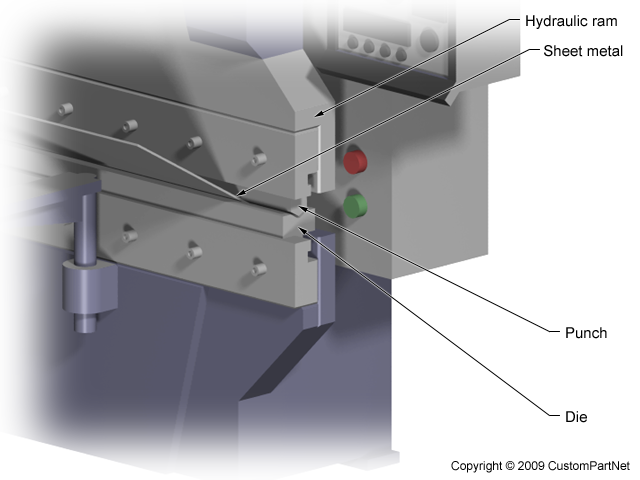

Metal Brake Diagram

It seems like an imposing tool to master but its really just a large clamp with a moving.

Metal brake diagram. Handles material as thick as 16 gauge. Just narrow your search by choosing tapco or van mark and the brake model then look at the helpful diagrams to assist you in choosing the correct part. The bending brakes design allows for a full 90o capacity in steel as thick as 16 gauge and can handle stock up to 18 in. Stainless steel brake lines over 120 skus covering popular dodge ford gm and jeep trucks.

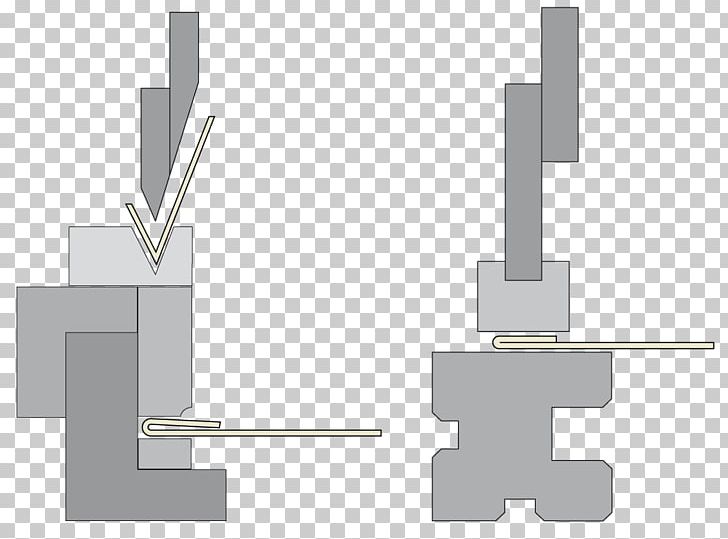

Simple sheet metal brake. When you purchase it the suppliers will send you the wiring diagram together with the hydraulic diagram as well as the installation and operation manuals. Every siding contractor and most roofers have one. Stainless steel brake lines carry pressurized fluid from the master cylinder to the wheels.

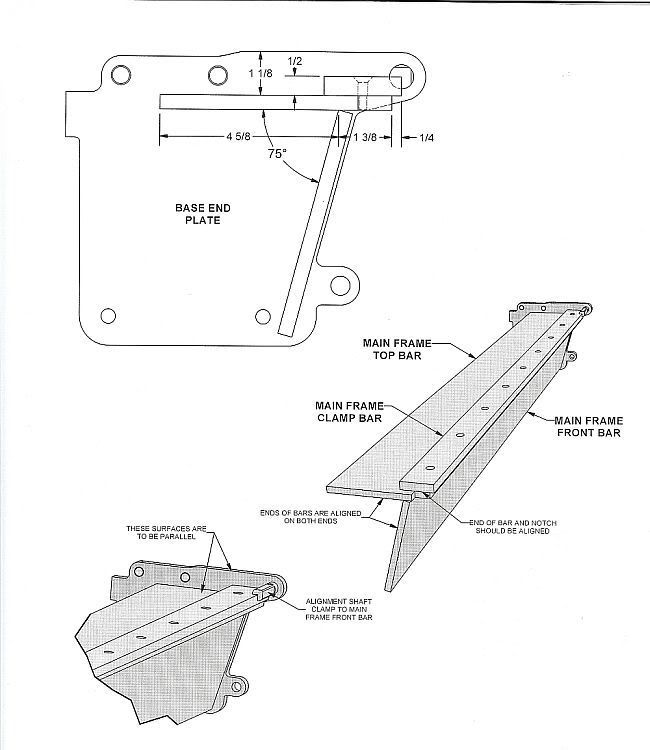

Easily clamps or mounts to workbench. In order to keep your aluminum siding brake in good working order you can simply buy separate parts to replace existing worn out damaged broken or missing ones. Generally ill stick the piece to be bent in the vise and smack it around until its bent. Here youll see a wide selection of sheet metal brakes for bending steel aluminum or stainless sheet metal and various other flat materialsbox and pan brakes or finger brakes have removable fingers to allow complex bending not attainable with straight brakes.

Sheet metal brakes are machines designed to make bending thin metal into shapes for use in projects such as house siding eaves air conditioning ductwork and others. If you did not see it when you receive the machine please contact your supplier. Thanks to heavy steel construction these box brakes will remain accurate over a lifetime of use. Different manufacturers will design different press brake wiring diagram.

This line ranges from a 2 foot 16 gauge small metal brake to a mighty 13 foot 22 gauge machine. But a brake can come in handy for all sorts of projects. How to build a small sheet metal brake. Since it almost always bends crooked i end up rebending and generally jus.

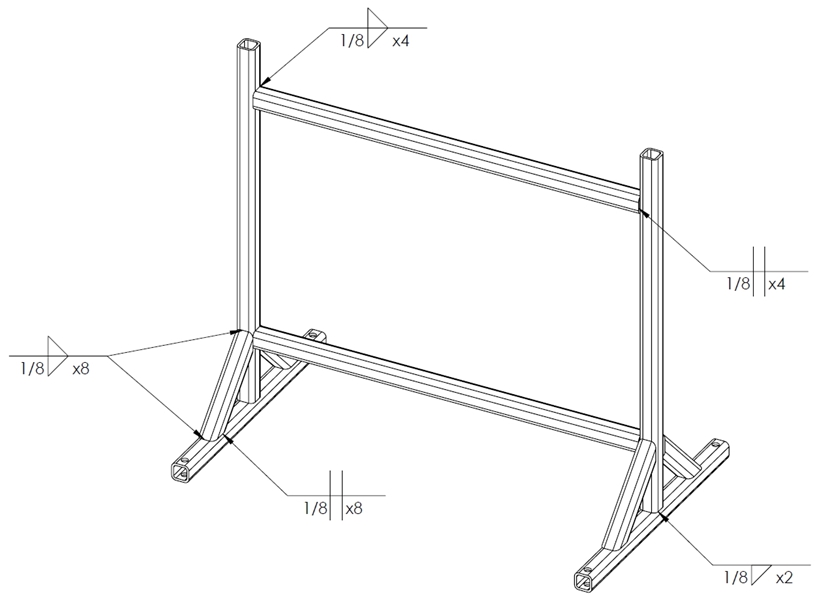

The brake is compact and lightweight yet sturdy enough for professional production runs. Pressure tested and backed by the dorman limited lifetime warranty. Press brake wiring diagram. 12 tips for bending metal with a bending brake.

8 to 16 hardened fingers of various lengths enabling you to make a wide range of boxes and pans. Find the working length and gauge capacity that best fits your needs. Each sheet metal finger brake offers. I love working with metal but ive always struggled to get perfect 900 bends.

Bends metal up to 18 in.