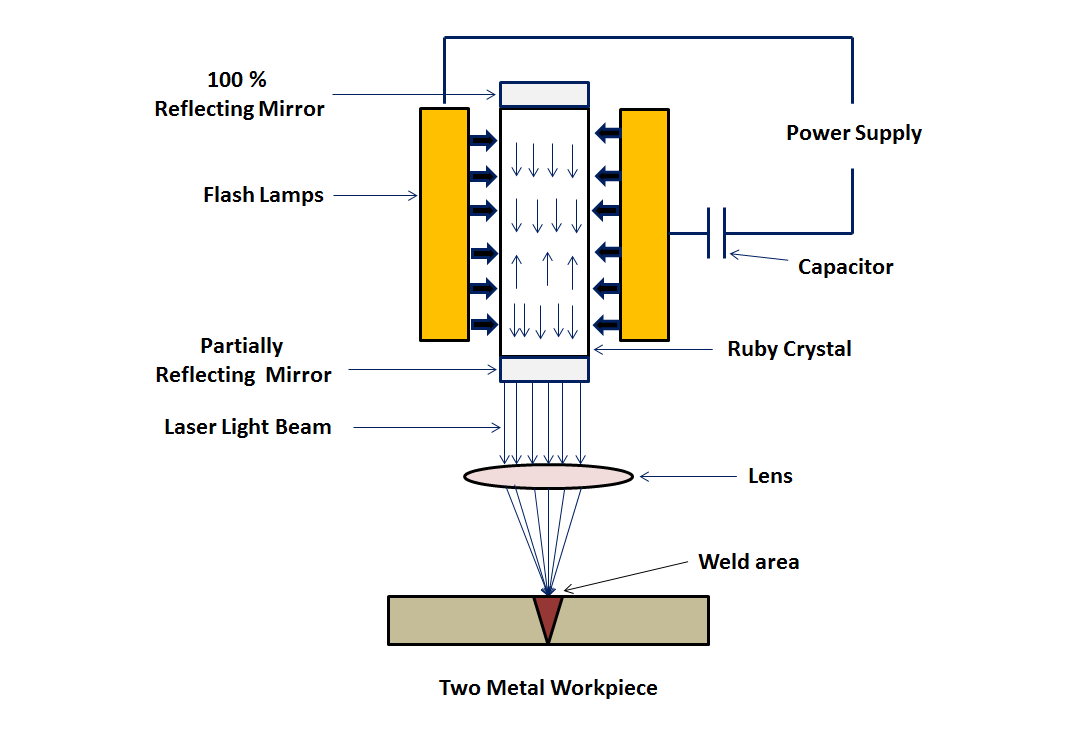

Laser Welding Diagram

In laser welding a concentrated coherent light beam impinges at the desired spot to melt and weld the metal.

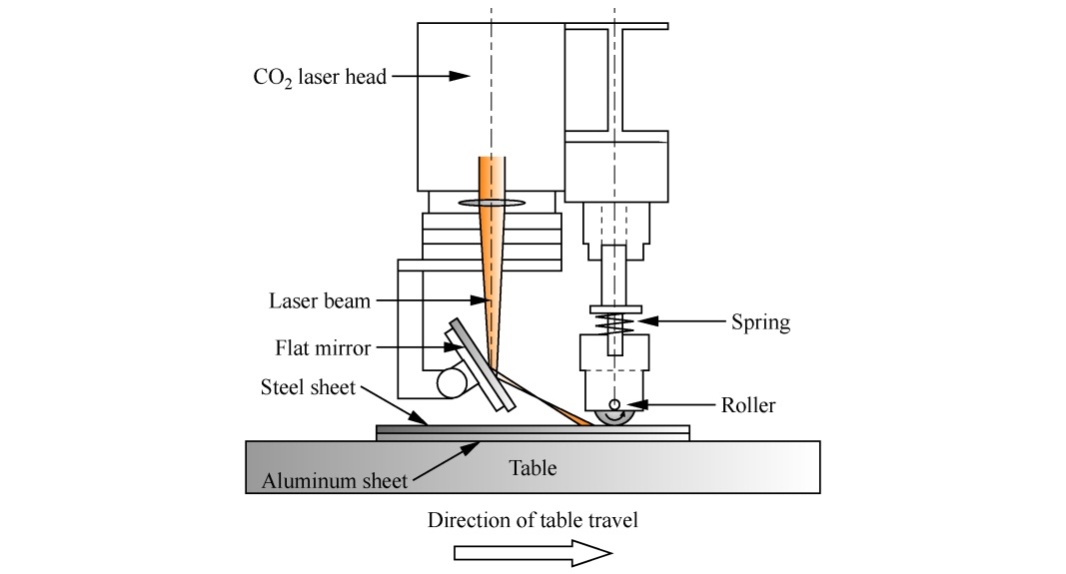

Laser welding diagram. In laser welding the absorption of energy by a material is affected by many factors such as the type of laser the incident power density and the base metals surface condition. After reading this article you will learn about the setup for laser welding with the help of diagrams. Laser stands for light amplification by stimulated emission of radiation. Laser beam welding energy transfer is different than arc welding processes.

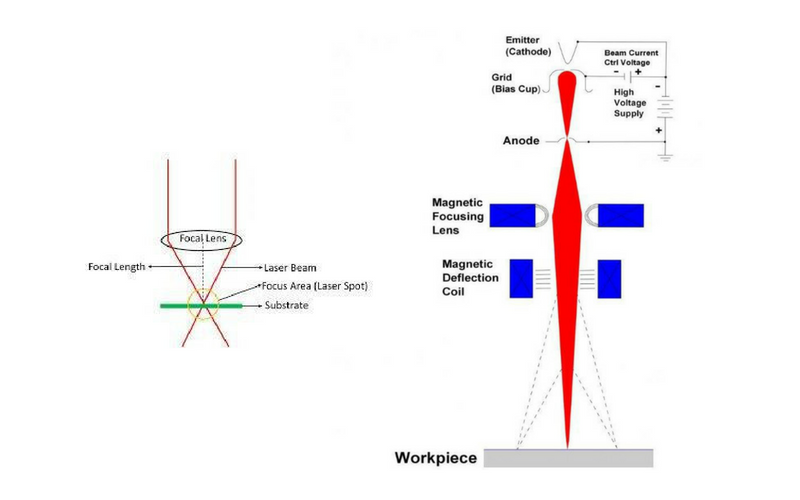

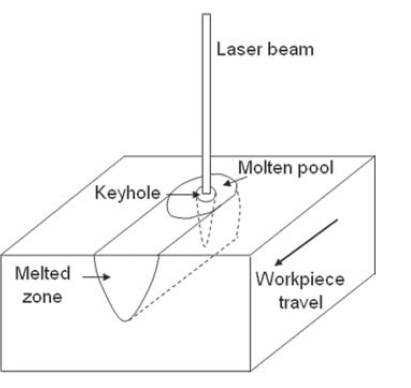

If the beam is focused on a metal surface it can raise the temperature to melting. Laser beam welding lbw is a welding technique used to join pieces of metal or thermoplastics through the use of a laserthe beam provides a concentrated heat source allowing for narrow deep welds and high welding rates. Provides you greater technological reach fast turnaround time quality and flexibility while helping you to reduce your costs. The laser beams have enough energy and when it strikes the metal pieces produce heat that melts the material from the two metal pieces and fills the cavity.

The laser pulse energy was ad justed to study the effect of weld shape and solidification conditions on mi crostructure and associated cracking sus ceptibility. These results were then com pared to the behavior predicted using the suutala diagram fig. The word laser stands for light amplification by the stimulated emission of radiation. Laser welding is an excellent substitute that frequently outperforms arc welding processes and its tightly focused beam limits heating effects.

The process is frequently used in high volume applications using automation as in the automotive industryit is based on keyhole or penetration mode welding. Laser beam welding process in general cases heat is required to fuse the metals for any types of welding in laser beam welding process the heat is obtained from the application of a concentrated coherent light beam which striking upon the weld metal and melt the metal such this weld joint is obtained this welding process is called laser welding. Laser welding is capable of welding tasks beyond the capability of traditional welding methods. Laser beam welding with diagram.

Welded using the pulsed laser welding process. The laser beams are focused to the cavity between the two metal pieces to be joined. A coherent light is. Fiber laser is scalable with laser powers available at multi kilowatt levels used for penetration welding applications up to and beyond 025 inch thickness.

A laser welding device amplifies an input of light producing an extremely narrow and intensive beam on the weld surface with deep penetration.