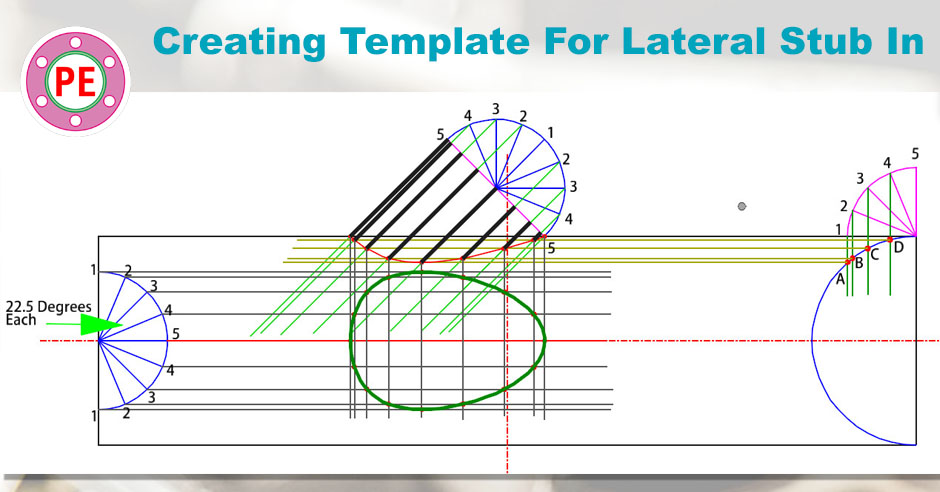

Tube Cutting Template

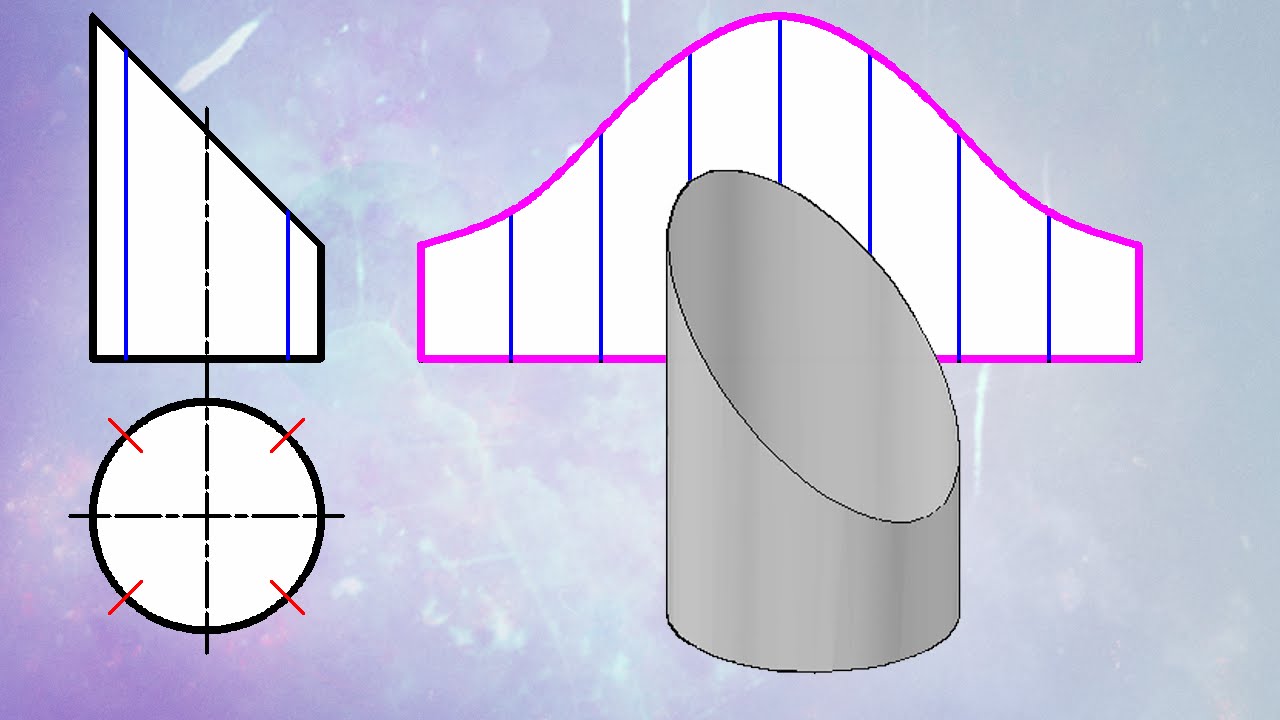

Tube and pipe notching calculator full scale printable templates if cut tube wall thick is larger than 0 the cut fits to the inside diameter of the tube making a notch for welding.

Tube cutting template. In the generated templates the color of cut lines where a tube intersects the outside of another tube is the same as the color used to show that intersecting tube in the 3d model. When doing accurate work using just hand tools you only want to cut a line you can see. If wall thickness is enabled then cut lines where a tube intersects the inside are drawn in grey. Tube coping calculator.

To find pipe end shape not hole in sheet enter 0 for sheet thick. Cut and use template to mark and cut sheet to fit pipe at angle. Tube joint pattern generator. Your one stop shop for 3500 laser cut and engrave templates designs patterns.

For a snug fit at the outside of the tube enter 0 cut tube wall thick and grind inside of tube to fit. Dont try to cut through to the backside of the tube. For larger pipes or if you dont have a miter saw handy print templates at 100 printer scale cut and wrap around pipe to mark the miter cut. Welcome to laser ready templates.

Wrap it cut is a magnetic template for producing accurate pipe cutes for 90 degree 45 degree and coped welded joints as well as straight end cuts. Print template at 100 printer scale. Cut carefully just a bit proud of the line. Remember only cut to the line you can see.

Buy tried and tested templates ready for your laser creations. Or check plot points to calculate and display lateral measurements at set increments around the pipe to mark the cut line for the miter. Rotate the tube in your tubing blocks cut again. Use your favourite editing program to scale true vectors and add or remove elements to personalise the design.

Kick start your new product range in minutes. The point of this thing is to create a cutting pattern for a tube or a pipe to accurately fit it at an angle to another tube or pipe so that you can weld or braze it. Learn the tricks to rotary cutting around acrylic templates no matter the shape. This is a whole lot easier than eyeballing the cut and scribing it by hand and if you do it right both the grinding and welding are pretty easy.