Pipe Angle Cutting Template

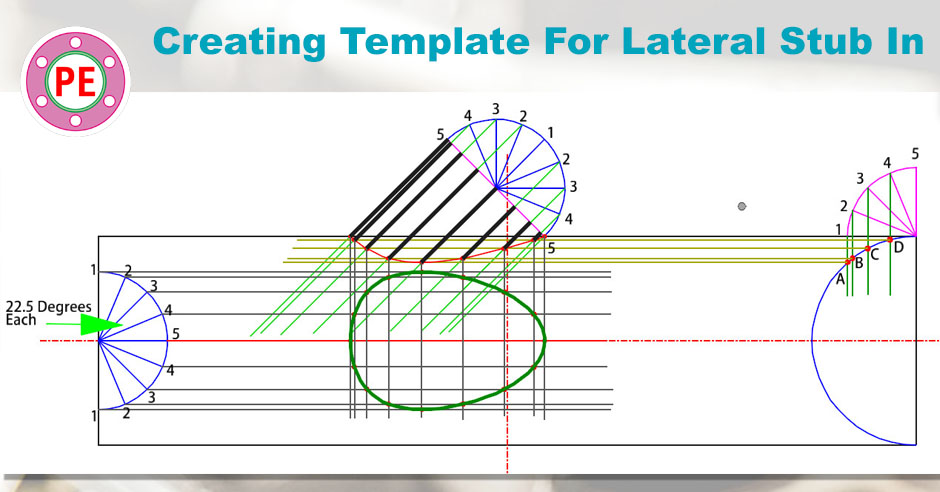

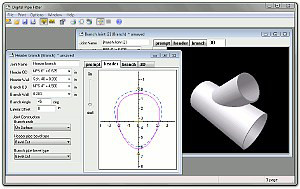

Or check plot points to calculate and display lateral measurements at set increments around the pipe to mark the cut line for the miter.

Pipe angle cutting template. Lee company which is a wrap mark and cut deal as long as its a 90 45 225 or tee. Wrap mark cut and grind to shape metric. This is a whole lot easier than eyeballing the cut and scribing it by hand and if you do it right both the grinding. Because the 2 sides of the template are exact opposites if you can fit half of a large template completely on a page you can mark half 1800 of the pipe then reverse flip the half template to mark the other side.

Tube coping calculator. This last summer i was contacted my father who needed to layout the pattern for a saddle cut for an irrigation system he was installing. I bought a set of pipe cutting templates from re. Draw a circle under the vertical pipe and divide it into 16 equal spaces and number as shown.

Here is how i do it. Calculate print and cut pipe coping templates. Pipe tube notching join profile diagram. This is also a handy way to mark a notch cut if youre on site with a phone or tablet and cant print the templates.

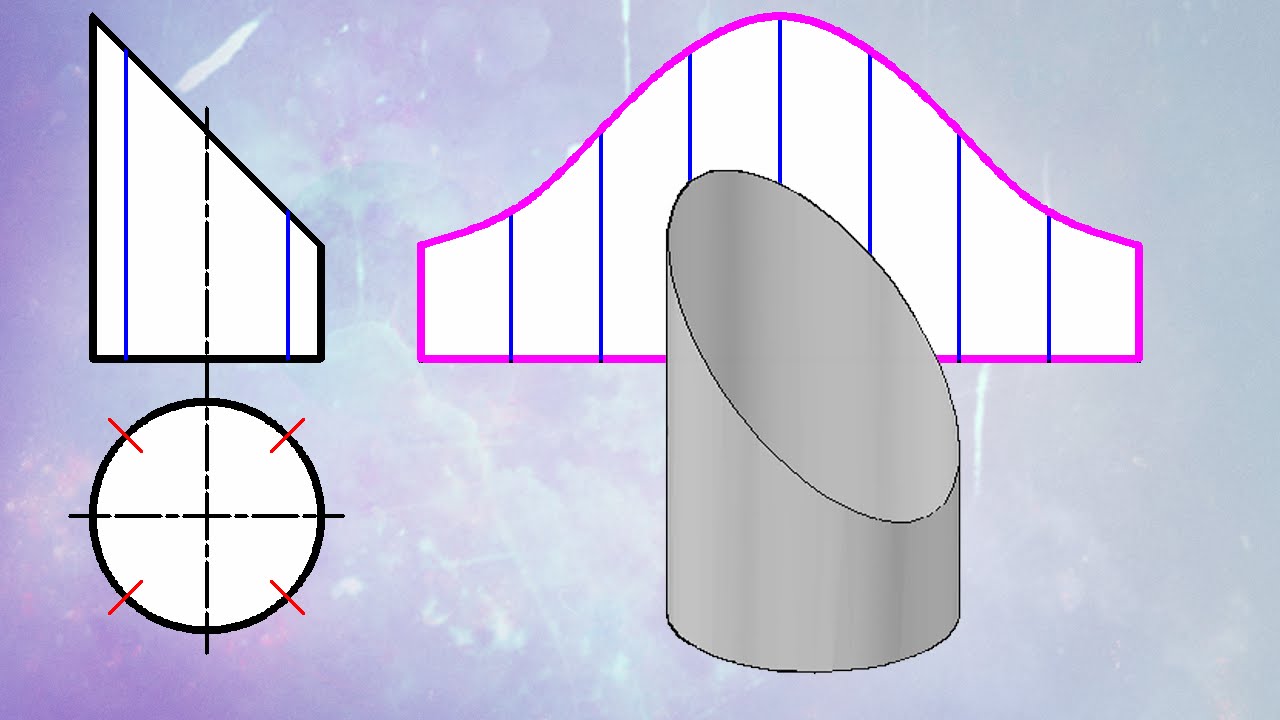

To find pipe end shape not hole in sheet enter 0 for sheet thick. How to layout a pipe saddle cut. Cut and use template to mark and cut sheet to fit pipe at angle. Here is a brief example of making a pipe template using parallel line development.

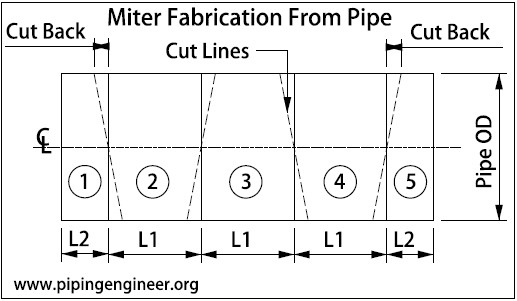

The example below is for a mitered elbow on 2 38 od tubing. Draw a view of the pipes that shows the angle of intersection. Select angle increment and hit full set to generate and print a full set of oval templates for currently entered pipe diameter. What is the best way to layout a cut line on large diameter pipe for lets say a 45 degree cut.

Select angle increments and hit full set button to draw a set of templates at each selected angle increment for current pipe diameter and wall thickness entries. In case its not entirely obvious the point of this thing is to create a cutting pattern for a tube or a pipe to accurately fit it at an angle to another tube or pipe so that you can weld or braze it.